Dominion Engineering, Inc. AMFMTM filtration technology utilizes a patented ultrasonic regeneration process, which allows each AMFMTM filter to be re-used many times over a very long service lifetime. This significantly reduces filter management and disposal costs when compared to traditional filtration approaches. Commercial nuclear plants have reported annual savings on the order $500,000 to $1,000,000 per year when transitioning from traditional disposable filters to AMFM-based filtration systems.

AMFM-X750 & AMFM-X1500 Filtration Systems

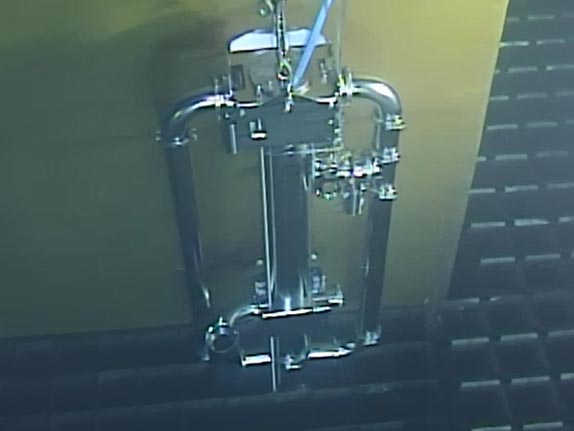

Similar to earlier generation AMFM-B500 and AMFM-P500 filtration systems, AMFM-X750 (750 gpm) and AMFM-X1500 (1500 gpm) are submersible filtration systems that use a patented ultrasonic regeneration process to refresh the capacity of their AMFM filters, thereby eliminating manual filter changeouts. Filter regeneration is automated and requires no human intervention. The AMFM-X750 and AMFM-X1500 designs incorporate several enhancements relative to earlier generation systems, including shorter AMFM filters and distinct active and sacrificial filters to increase flexibility in management and ultimate disposal, and placement of filters upstream of the pump to minimize pump contamination and dose rates. These systems are compatible with any plant type and support extended hands-free filtration/vacuuming in pools and cavities.

AMFM-B500 Filtration System

The AMFM-B500 filtration system is a compact system designed for underwater filtration and vacuuming activities in the spent fuel pool and reactor cavity at BWRs. The system includes one BWR-type AMFM™ filter, hanging frame, 500-gpm pump with remotely-removable inlet debris strainer, ultrasonic regenerator and topside control unit. Each BWR-type AMFM™ filter has the same interfaces and envelope dimensions as a BWR fuel bundles so that it can be easily handled and stored in the fuel rack when not in use. When needed, ultrasonic regeneration of the AMFM™ filter is initiated using a single button on the topside control unit, which eliminates labor intensive plastic filter changeouts during refueling outages.

AMFM-P500 Filtration System

The AMFM-P500 filtration system is a compact system designed for underwater filtration and vacuuming activities in the spent fuel pool and reactor cavity at PWRs. The system includes one PWR-type AMFM™ filter (same interfaces and envelope dimensions as a PWR fuel bundle), hanging frame, 500-gpm pump with remotely-removable inlet debris strainer, ultrasonic regenerator and topside control unit. The system also includes several other design features that facilitate transfer of the AMFM™ filter between the fuel pool and containment at PWRs, and use of the AMFM-P500 system in either location. When needed, ultrasonic regeneration of the AMFM™ filter is initiated using a single button on the topside control unit, which eliminates labor intensive plastic filter changeouts during refueling outages.

Skid-Mounted AMFM™ Filtration Systems

In addition to submerged systems such as the AMFM-B500 and AMFM-P500, Dominion Engineering, Inc. has also developed a number of skid-mounted configurations which incorporate its AMFM™ regenerable filtration technology. These systems have been successfully deployed for waste retrieval and processing activities at DOE sites, as well as vacuuming activities outside of the spent fuel pools at commercial reactors (such as the torus, suppression pool, and sump under the reactor vessel). Similar to the fuel-bundle shaped AMFM™ filters, the filter elements in these skid-mounted systems can be ultrasonically-regenerated, allowing them to be safely stored and reused for future applications. During regeneration, particulate collected on the filter elements can be transferred to an external vessel or an AMFM-B500 or AMFM-P500 system.

Dual-Axis Robotic Vacuuming Arm (DARVA™)

Dominion Engineering, Inc. supplies a catalogue of cleaning and vacuuming attachments designed for use with the AMFM-based regenerable filtration systems. One such tool is DARVA™, a robust dual-axis robotic vacuuming arm designed for efficient removal of settled sediment and hard heels from tanks and vessels. DARVA™ can be quickly installed and remotely-operated using simple joystick controls, making it ideal for deployment in challenging radiological environments. Along with a skid-mounted AMFM™ regenerable filtration system, DARVA™ was recently deployed in a novel undervessel sump vacuuming application at LaSalle Station which significantly reduced radiological exposure to workers performing maintenance activities under the reactor vessel during a recent refueling outage. LaSalle was awarded 1st place at Exelon’s 2019 Innovation Expo for this project.