Dominion Engineering, Inc. serves as a technical consultant to numerous EPRI Guidelines committees related to water chemistry, radiation protection and fuel reliability. Our expertise in these areas includes:

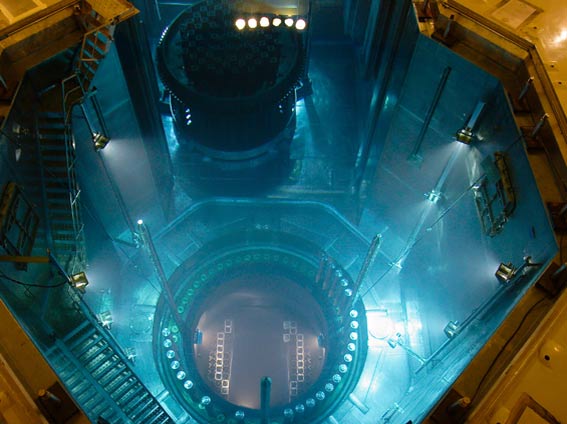

Utility Consulting: Effective water chemistry programs ensure fuel and material reliability and radiological performance objectives are achieved, while minimizing direct costs and impact to plant operations. Dominion Engineering, Inc. regularly assists utilities by providing objective and quantitative analysis to support optimization of water chemistry practices. In a recent example study, Dominion Engineering, Inc. assisted a US utility with the following:

A key benefit of these studies is that Dominion Engineering, Inc. recommendations are supported not only by independent analysis, but also benchmarking against US and non-US operating experience.

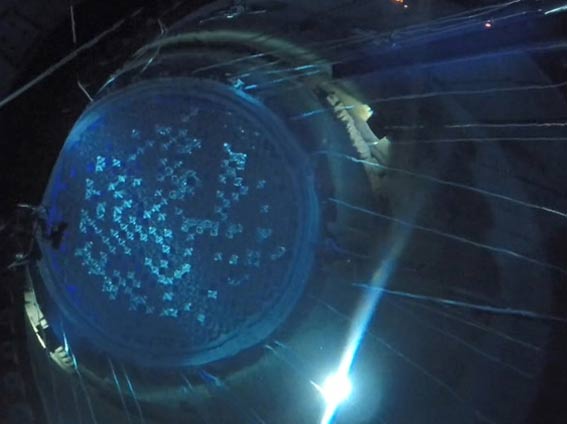

Root Cause Investigation: When properly analyzed, water chemistry data can provide significant insights into factors contributing to elevated dose rates and radiation exposure to workers. Recently, a two-unit BWR site observed a divergence in chemistry and radiological performance between the two units and Dominion Engineering, Inc. provided an independent root cause investigation and assisted the utility in prioritizing corrective actions to resolve the issue. Key findings and results achieved as a result of Dominion Engineering, Inc. consulting study were as follows:

Dominion Engineering, Inc. has continued to work with this utility to further optimize radiological performance and minimize recontamination during subsequent plant operation.

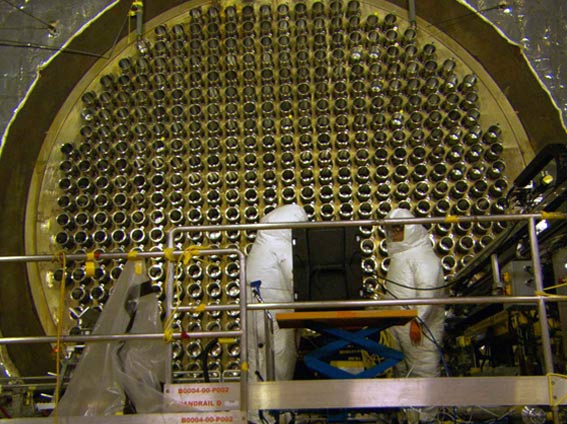

Independent Consulting: When a reactor is being exported, there are often gaps between technical information and justifications provided by the reactor supplier in the country of origin and that required by the regulator in the country of import. In a recent example project, Dominion Engineering, Inc.assisted an advanced reactor supplier with the general design assessment process for a foreign nuclear regulator. The following assistance and insights were provided:

Dominion Engineering, Inc. independent technical support was effective in justifying the advanced reactor design / operational practices to the local authorities and supporting regulatory acceptance of this advanced reactor design.

Impact Assessment: Dominion Engineering, Inc.was the principal investigator for EPRI report 3002005335, and regularly assists utilities both in developing effective water chemistry control strategies during extended outage periods and managing any startup chemistry excursions which occur after outages. In a recent project, Dominion Engineering, Inc. provided the following technical support when a CANDU unit experienced a sulfate excursion in steam generator (SG) blowdown during startup from an extended refurbishment outage.

Since return to power, this unit has continued to operate safely and reliably with no material degradation or performance issues attributable to the startup chemistry excursion.

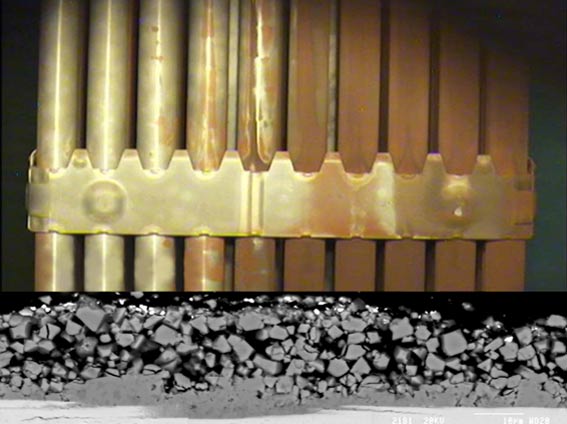

Technical Evaluation & Experimental Validation: Foreign material can enter nuclear reactor systems during maintenance activities and as a result of component degradation. Recently, when plant operating experience highlighted high potential for an elastomeric component to degrade and enter the reactor system in a BWR plant design, Dominion Engineering, Inc. assisted a utility in evaluating the consequences of this event on plant integrity and performance. Specific assistance and insights provided by Dominion Engineering, Inc. in this study included.

The component was later replaced with the alternate material recommended by Dominion Engineering, Inc. and the component has performed reliably with no foreign material ingress to plant systems.