Dominion Engineering, Inc. provides engineering analysis and scientific consulting services for safe and reliable design, startup and operation of radioactive waste processing facilities and geological repositories, many of which have unique technical requirements and considerations. Additionally, Dominion Engineering, Inc. provides specialized products and technology, and consults on the design and development of custom equipment for automating and improving decommissioning and nuclear waste management activities. Our decommissioning and waste management expertise includes:

Technical Consulting and Custom Equipment Design: When processing radioactive waste, it is important to minimize the number of filters required and simplify filter changeouts to minimize downtime and worker exposure. Recently, during waste processing activities at a DOE site, rapid filter clogging and high frequency of filter changeouts were observed when using a traditional filtration system, and Dominion Engineering, Inc. was contracted to assist in restoring system performance. Dominion Engineering, Inc. technical support included:

The modified system was helpful in maintaining favorable performance and providing a convenient and effective means for periodic regeneration of the filters, minimizing downtime and worker exposure by eliminating traditional filter changeouts.

Multi-physics Modeling and Experimental Validation: Deep geological repositories are designed to safely contain and isolate nuclear waste from the environment for significant durations (thousands to millions of years). Despite the robust engineering controls and stable geologic formations used for safe storage, the extended design isolation period requires rigorous engineering analysis and testing to justify. Dominion Engineering, Inc. performed numerous engineering analysis and testing activities in support of the Yucca Mountain nuclear waste repository in the US, including:

Dominion Engineering, Inc. also provides consulting services related to material integrity and in-service inspection of spent nuclear fuel storage canisters at independent spent fuel storage installation (ISFSI) facilities, as well as spent nuclear fuel transportation and containment systems.

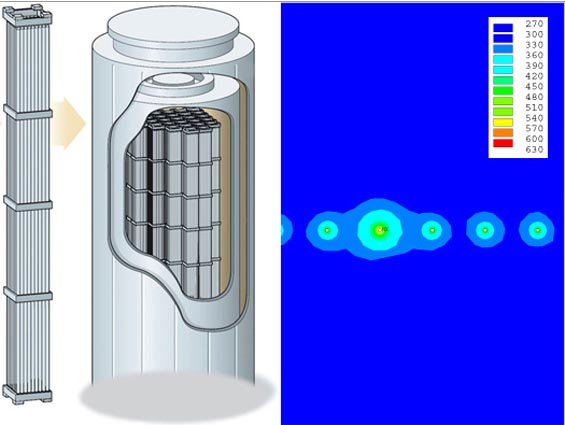

EPRI Research Program: Decommissioning and dismantling of nuclear facilities involves a number of manual tasks with extended durations. Remote delivery and automation of these tasks can reduce the cost, risk, schedule and radiological exposure associated with these activities. Dominion Engineering, Inc. supported EPRI research program to automate reactor vessel internals segmentation and waste packaging activities during decommissioning. Dominion Engineering, Inc. technical support included:

Dominion Engineering, Inc. has completed similar process automation and tooling design projects for fluidization and removal of hard heels and sediment from waste tanks and vessels, and remote delivery of concrete decontamination tooling.

Engineering Consulting for Material, Mechanical and Fluidic Issues: Nuclear waste processing facilities typically include a number of unique processes and equipment. Careful engineering and technical studies are required to properly design these facilities and ensure reliable operation. During recent startup of a radioactive waste treatment facility at a DOE site, Dominion Engineering, Inc. assisted the O&M contractor in evaluating and resolving a number of unique technical issues. Dominion Engineering, Inc. assistance and insights included:

Dominion Engineering, Inc. analysis and supporting experimental investigations were beneficial for resolving technical issues identified during initial trials and startup of the waste treatment facility.