10th BWR Plant Safely Completes HE-UFCTM Ultrasonic Fuel Cleaning

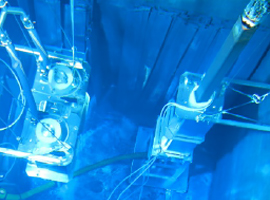

Based on favorable industry experience, the use of high efficiency ultrasonic fuel cleaning (HE-UFCTM) continues to expand rapidly at BWR plants. With a majority of the source term present in fuel crud at BWRs and very high cleaning efficiency demonstrated, HE-UFCTM applications have resulted in significant radiological benefits at BWRs. Additionally, through the removal of debris present on fuel bundle bottom nozzles, HE-UFCTM has been credited with arresting debris-induced failures at two BWRs, thereby demonstrably improving fuel reliability. As a result, many BWRs are now performing HE-UFCTM not only to improve radiological performance, but also in response to recommendations in INPO IER L2-19-6 for preventing debris-induced fuel failures.

BWR ultrasonic fuel cleaning activities have proceeded conservatively, in some cases with the number of fuel bundles subjected to HE-UFCTM being limited during the first few applications at BWR plants to allow for enhanced fuel surveillance activities. However, after years of extensive qualification testing, peer reviews and fuel examinations, no fuel integrity issues attributable to HE-UFCTM have been identified at BWR plants. With the Spring 2020 outage season marking successful completion of the 10th BWR HE-UFCTM campaign, many BWR plants are now pursuing full reload ultrasonic fuel cleaning campaigns. This means that all reload fuel bundles are cleaned prior to reloading, an approach that maximizes the radiological and fuel reliability benefits that can be achieved by HE-UFCTM.

DEI looks forward to continuing to assist our BWR clients in achieving their radiological performance and fuel reliability objectives.