BNDE Effectively Mitigates Debris-Induced Fuel Failures

Bottom nozzle debris elimination (BNDETM) has proven to be an effective process for preventing and mitigating debris-induced fuel failures at boiling water reactors (BWRs) and the cleaning process can also be applied at pressurized water reactors (PWRs). A number of plants have performed BNDE cleanings as a preventive measure as part of their response to INPO Event Report (IER) L2-19-6, “Preventing Debris-Induced Fuel Failures.” Other sites have performed BNDE cleanings as a corrective measure. In all of these cases, BNDE has been effective in mitigating persistent debris-induced fuel failures during subsequent plant operation.

When foreign material enters the reactor system, either during maintenance activities or as components degrade, this material can be transported to the fuel bundles and cause a fuel failure. Before this occurs, foreign material typically becomes trapped on the lower debris screen in the fuel bundle bottom nozzle for some period of time, providing an opportunity to remove the debris before it causes any fuel damage.

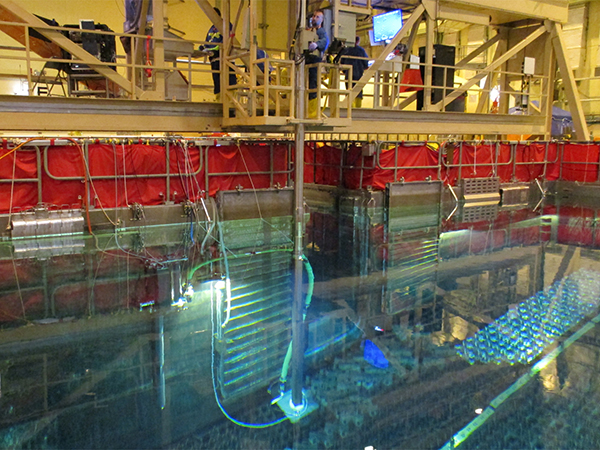

DEI’s patented BNDE equipment uses a combination of ultrasonic energy and vacuuming to remove and positively capture any debris present. The cleaning process takes several minutes per fuel bundle and has proven to be a practical and effective way to remove potentially damaging debris without a significant impact on the outage schedule or on other refueling activities.

The BNDE equipment is an adaptation of DEI’s full length high efficiency ultrasonic fuel cleaning (HE-UFC) system, which has been safely used in hundreds of applications at PWR units to improve fuel performance and radiological conditions, in addition to achieving debris and foreign material removal. To date, 20 BNDE and HE-UFC fuel cleaning campaigns have been successfully completed at BWRs. Three of the BWR units that have performed BNDE or HE-UFC were experiencing active debris-induced fuel failures prior to these operations and in all cases, the debris-induced fuel failures were arrested as a result of the cleaning activity.

When BNDE has been performed, debris and foreign material has typically been observed on the bottom nozzle of 25-50% of the fuel bundles prior cleaning. Industry experience has shown that the BNDE cleaning process is effective in removing debris from approximately 90% of the fuel bundles identified to have debris present, significantly reducing the risk of a fuel failure during future operation. Once collected, some sites perform analysis of the debris and foreign material collected in order to identify the composition and possibly the source of the material, and to plan any further mitigative measures.

“For more than 20 years, DEI has performed full length ultrasonic fuel cleaning at PWR sites to effectively manage crud-induced power shift (CIPS) / axial offset anomaly (AOA) and to support zinc injection programs for dose rate reduction,” said DEI President Mike Little. “We are excited to now be using our BNDE technology to assist BWR and PWR sites in enhancing fuel reliability by reducing the risk of debris-induced fuel failures.”

For more information regarding the use of BNDE or HE-UFC fuel cleaning to prevent or mitigate debris-induced fuel failures, please contact info@domeng.com.