Dominion Engineering, Inc. serves as a technical consultant to the EPRI Material Reliability Program, Steam Generator Management Program, BWR Vessel and Internals Program and the ASME Task Group on in-service inspection of Spent Nuclear Fuel Storage and Transportation Containment Systems. Our corrosion and materials expertise includes:

EPRI RESEARCH PROGRAM: Following discovery of boric acid corrosion of a reactor vessel head, Dominion Engineering, Inc. led a multi-year EPRI research program to establish and justify inspection protocols for control rod drive mechanism (CRDM) nozzles to ensure safe plant operation and protection of the public and environment. Dominion Engineering, Inc. support of this effort included:

Dominion Engineering, Inc. modeling methods were reviewed and accepted by the US NRC, and this body of work culminated in numerous technical reports and industry guidance documents, including EPRI’s Boric Acid Corrosion Guidebook.

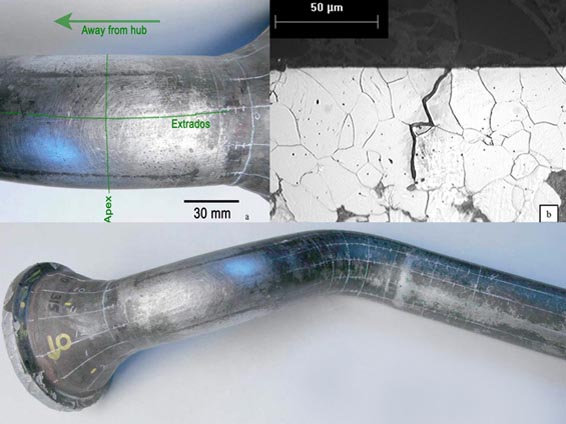

UTILITY CONSULTING: For more than 15 years, Dominion Engineering, Inc. has performed assessments of feeder pipe and fuel channel degradation at CANDU plants, including cracking, flow accelerated corrosion (FAC), and other integrity issues. Some examples of our work include:

Dominion Engineering, Inc. has presented its results to the Canadian regulator on behalf of several CANDU utilities, and these results have been accepted as the technical basis for establishing appropriate inspection intervals.

UTILITY CONSULTING: PWR and CANDU steam generator (SG) tubing experiences degradation by a number of mechanisms including stress corrosion cracking, tubesheet denting, and tube support plate blockage. Dominion Engineering, Inc. assists utilities in the development and implementation of programs to optimize the economics of SG inspection and maintenance and ensure long-term SG reliability. In a recent example project, Dominion Engineering, Inc. provided the following services:

Dominion Engineering, Inc. technical support assisted the utility in performing corrective maintenance to arrest active degradation in some units, and to perform proactive maintenance to avoid SG replacement at other units, saving the utility on the order of $100 MUSD.

ROOT CAUSE INVESTIGATION: Prior to its retirement in 2018, Canada’s National Research Universal (NRU) reactor produced essential medical isotopes used to treat cancer and diagnose other illnesses. In 2009, the NRU reactor was temporarily shutdown due to corrosion of the aluminum reactor vessel. At that time, only one of the other four worldwide medical isotope sourcing reactors was in operation, leading to a global shortage in essential medical isotopes. Thus, safe and efficient return to service of the NRU reactor was a top priority. Dominion Engineering, Inc. provided significant material expertise and consulting in support of this objective, including:

Dominion Engineering, Inc. technical insights were beneficial in helping to return the NRU reactor to service and ensuring continued reliable operation until this research reactor was later retired in 2018.