In addition to our established suite of Products & Technology, Dominion Engineering, Inc. assists clients in the development and application of creative equipment and process solutions for unique applications. Our expertise includes:

Independent Design Review: Laser peening has been used extensively in other industries to mitigate stress corrosion cracking in susceptible components. Dominion Engineering, Inc. has supported EPRI, utilities and laser peening service providers during the development and qualification of laser peening for nuclear components. Example technical support includes:

Dominion Engineering, Inc. technical support contributed to acceptance of laser peening for nuclear components and successful deployment for stress mitigation of bottom-mounted nozzles. The technology has since been applied to spent nuclear fuel canisters and application to control rod drive mechanism (CRDM) nozzles is planned.

Independent Technology Downselection: During inspections, Bruce Power identified stress corrosion cracking in the calandria relief ducts at Bruce B Unit 7. This was a unique challenge for which there was no “off-the-shelf” repair solution. After development of tooling to support limited repair and full-length inspection, Bruce Power determined that cracking was more substantial than expected such that the planned repair equipment and strategy was not viable. Dominion Engineering, Inc. was subsequently contracted to assist in evaluating and developing alternate repair strategies and equipment. Specific Dominion Engineering, Inc. services provided included:

Dominion Engineering, Inc. technical support has assisted Bruce Power in objectively evaluating and narrowing down repair strategies and technologies to consider for this unique challenge, and to select and develop custom deployment tooling to implement the needed repairs.

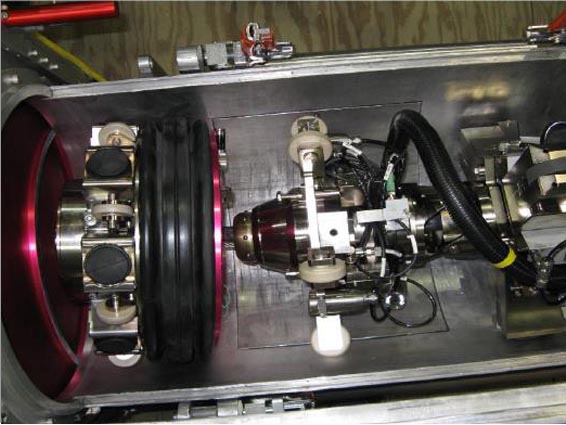

Adaptation of NU-DECTM System for Novel Application: Cement solidification systems are used to encapsulate a variety of nuclear waste streams. By nature, these systems are prone to performance degradation due to fouling with cementitious deposits. In a recent project, Dominion Engineering, Inc. assisted a customer in adapting its NU-DECTM product line to restore the performance of a degraded cement solidification system. Dominion Engineering, Inc. technical support included:

The adapted NU-DECTM system and process were effective in cleaning cementitious deposits and restoring the performance of the cement solidification system without the need to open or enter system components.

Conceptual Design Study: Generation IV nuclear reactors operate at much higher temperatures than currently operating reactors. Thus, process heat can be used directly for efficient production of hydrogen and other carbon-neutral fuels. Under contract for Idaho National Lab, Dominion Engineering, Inc.developed a conceptual design for a nuclear hydrogen production plant. Dominion Engineering, Inc. technical support included:

Dominion Engineering, Inc. contributions were helpful in advancing scientific research of high temperature steam electrolysis technology toward industrial feasibility and concepts for integration with a Generation IV nuclear reactor.