Dominion Engineering, Inc. serves as a technical consultant to the ASME Pressure Vessel & Piping (PVP) High-Pressure Technology Technical Committee and several ASME Boiler & Pressure Vessel (BPV) Standards Groups, including the Task Group on In-Service Inspection (ISI) of Spent Nuclear Fuel Storage and Transportation Containment Systems and the Working Group on Flaw Evaluation Reference Curves. Dominion Engineering, Inc. also consults on stress analysis and impacts on material cracking and degradation to the EPRI Material Reliability Program (MRP) Pressure Boundary Technical Advisory Committee (TAC), EPRI BWR Vessel and Internal Program (BWRVIP), and EPRI Fuel and High Level Waste Management Program. Our stress and dynamic analysis expertise includes:

EPRI Research Program: Dominion Engineering, Inc. has more than 30 years of experience in welding simulation and recently led a multi-year EPRI research program to validate residual stress models for dissimilar metal welds in nuclear components. As documented in EPRI reports MRP-316 and MRP-317 (3002005498 and 3002005499), Dominion Engineering, Inc. contributions to this effort included:

This project improved the understanding and quality of residual stress models for dissimilar metal welds. In addition to the research effort highlighted above, Dominion Engineering, Inc. also authored ASME Code Case N-899, which provides standardized welding residual stress distributions for use in flaw growth calculations.

Dynamic Response Analysis: For more than 15 years, Dominion Engineering, Inc. has supported design of the Hanford waste treatment plant as a key technical consultant, evaluating the risk and consequences of hydrogen accumulation and potential detonation when processing transuranic (TRU) waste streams. Dominion Engineering, Inc. contributions to this project have included:

Dominion Engineering, Inc. has presented technical findings and recommendations to the US DOE and the US DNFSB.

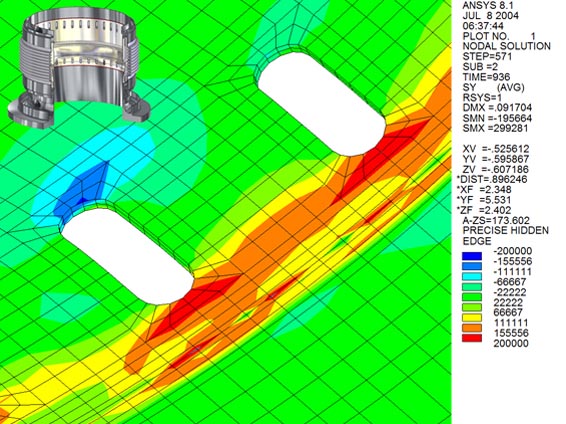

Root Cause Investigation: The line which feeds liquid hydrogen to space shuttle main propulsion systems includes a flexible joint which accommodates relative motion between the space shuttle structure and main engine. Cracks were detected in Inconel 718 flow liners in this joint for several space shuttles, including Atlantis, Discovery and Endeavor. In support of investigation of the issue by NASA’s Langley Research Center, Dominion Engineering, Inc. completed a root cause investigation of this issue. Specific assistance and insights provided by Dominion Engineering, Inc. in this investigation included:

These results contributed to NASA’s resolution of the issue, which included identification of appropriate inspection intervals and the development of a high resolution surface replication technique for precise detection of crack initiation locations.