Dominion Engineering, Inc. has significant expertise in modeling and analysis of thermal performance and fluid dynamics in industrial heat exchange equipment, and has authored a number of industry references on these topics, including chapters of Thermal Performance Degradation and Heat-Transfer Fouling and EPRI TR-110018 on thermal performance analysis methodologies. Dominion Engineering, Inc. serves as a technical consultant to the EPRI Steam Generator Management Program and EPRI technical committees on a number of topics, including: Plant Engineering, Dispersants and Filming Amines / Filming Products. Our thermal performance and fluid dynamics expertise includes:

Utility Consulting: Dominion Engineering, Inc. regularly performs consulting studies to assist utilities in assessing steam generator (SG) thermal performance losses due to corrosion product accumulation, and predicting future rates of thermal performance degradation. In an example study for a US utility, Dominion Engineering, Inc. provided the following assistance and insights:

The analyzed units achieved an 8-10 psi recovery in steam pressure by implementing maintenance activities recommended by Dominion Engineering, Inc. and avoided losses in power output by increasing their thermal performance margin relative to the valves-wide open condition.

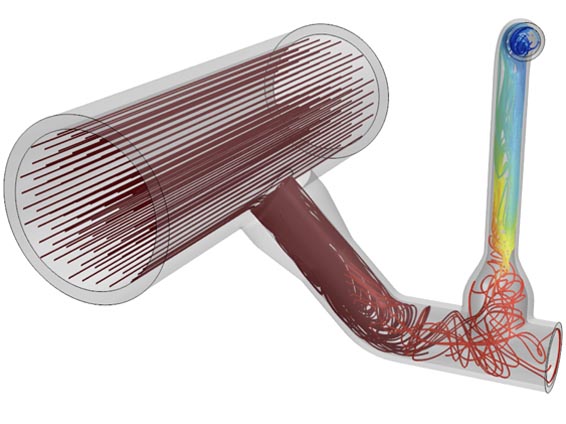

EPRI Research Program: Nuclear plants have experienced cases of material degradation and primary water leaks due to turbulence-driven thermal fatigue. Dominion Engineering, Inc. has supported a multi-year EPRI research program to develop high-resolution industrial models for thermal fatigue using computational fluid dynamics (CFD) and other numerical solvers. Dominion Engineering, Inc. efforts in this area have included:

The efforts above benefit the industry by reducing the risk of unplanned outages due to thermal fatigue degradation, while reducing O&M costs through optimized inspection intervals.

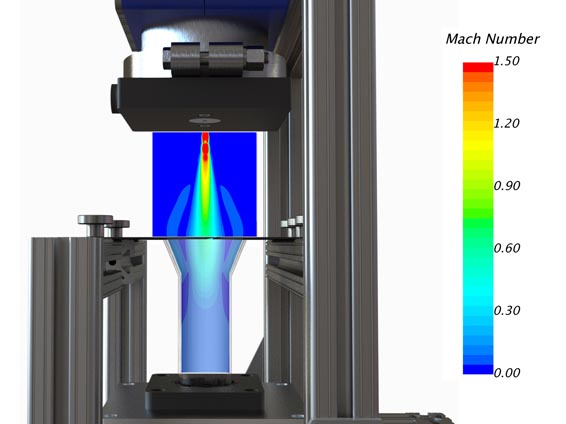

CFD Modeling & Experimental Validation: The integrated waste treatment unit (IWTU) in Idaho uses sonic gas pulses to backwash and regenerate gas filters operating at high temperature. Optimization of the gas pulse system and downstream Venturi block geometry is needed to ensure the desired performance is achieved, maximizing filter regeneration. Dominion Engineering, Inc. has provided the following technical consulting and support for this effort:

Dominion Engineering, Inc. modeling and experimental validation has supported improved understanding of the design and operation of both pilot-scale and full-scale plant conditions, and optimization of the process gas filters for reliable long-term operation.