From chemical treatments that extend the service life of nuclear components to innovative waste treatment technology, Dominion Engineering, Inc. develops and delivers specialized chemical processes to nuclear power plants and nuclear waste management and processing facilities for a wide range of applications.

Advanced Scale Conditioning Agent Treatment (ASCA™)

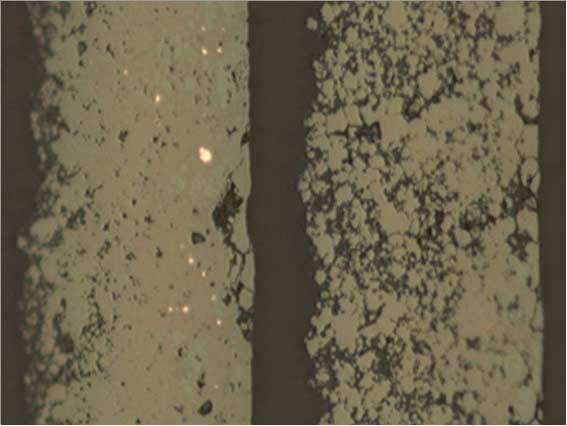

ASCATM is a unique chemical treatment that enhances thermal efficiency in steam generators (SGs) by modifying the structure of secondary tube scale in a beneficial manner. Typically, plants have observed steam pressure recoveries on the order of 10-15 psi upon return to power after ASCATM treatments. ASCATM applications also improve thermal hydraulics and extend SG service life through partial removal of harmful deposits that contribute to tubing degradation mechanisms such as denting, stress corrosion cracking, vibration and high cycle fatigue failures. The cost and complexity of ASCATM applications are significantly lower than for traditional SG chemical cleaning processes, and the corrosion, waste volume and environmental impact are also much lower.

LT-ZiP™ Dose Reduction & Passivation Treatment

LT-ZiPTM is a chemical treatment applied after chemical decontamination to mitigate recontamination during subsequent plant operation and preserve the dose rate reduction benefits achieved via chemical decontamination. LT-ZiPTM is applied at low temperature immediately after chemical decontamination (same refueling outage). The process deposits zinc and platinum on piping surfaces which becomes incorporated into protective oxides when the plant returns to power operation. The zinc serves to suppress the uptake of Co-60, Co-58 and other radioisotopes, while the platinum protects the piping from intergranular stress corrosion cracking (IGSCC). LT-ZiPTM and HE-UFC™ can also be performed concurrently to further mitigate recontamination after chemical decontamination. HE-UFC™ substantially reduces the source term available for recontamination as LT-ZiPTM suppresses radioisotope uptake during subsequent operation.

Chemical Decontamination & Waste Treatment

Dominion Engineering, Inc. has developed novel processes and systems for treatment of nuclear waste streams, including organic liquids and resins. This includes a process and system in which organic waste is passively converted to safe by-products using biological species, electrochemical waste destruction, consulting to develop an underwater plasma destruction process, and adaptation of a super critical water oxidation (SCWO) process for destruction of organic chemicals and resin waste from nuclear cleaning and decontamination applications. Dominion Engineering, Inc. also has expertise in electrochemical synthesis and has developed novel electrochemical processes for producing specialty chemicals for decontamination of nuclear systems. Dominion Engineering, Inc. also assists utilities in evaluating more traditional liquid waste treatment techniques to identify the most cost-effective option (incineration, solidification, RO, ion exchange, etc.).

Steam Generator Chemical Cleaning

Dominion Engineering, Inc. was integral to the original development of the EPRI/SGOG steam generator chemical cleaning process in 1980’s. For the last 40 years, Dominion Engineering, Inc. has continued to actively support utilities worldwide during preparation for and execution of steam generator (SG) chemical cleaning applications using the EPRI/SGOG process and processes later developed by others. Typical Dominion Engineering, Inc. services to utilities include independent assessments of current and projected SG conditions, review of technical / commercial bids submitted by service providers, independent process qualification testing, technical support during 50.59 screening evaluation (or equivalent regulatory and environmental evaluations required outside the US), and on-site consulting and corrosion monitoring during implementation of the SG chemical cleaning process.