An established technique for improving fuel reliability and radiological performance, Dominion Engineering, Inc. and its licensees have ultrasonically cleaned more than 4,000,000 fuel rods in 6 countries. Dominion Engineering, Inc. pioneered the use of high-powered ultrasonics for cleaning nuclear fuel and other critical systems and components, and has been delivering ultrasonic cleaning systems to the nuclear industry for more than 20 years.

High-Efficiency Ultrasonic Fuel Cleaning (HE-UFC™)

HE-UFC™ is a safe and effective way to remove activated corrosion products (commonly referred to as “crud”) and debris from PWR and BWR fuel bundles. HE-UFC™ has successfully mitigated crud induced power shift (CIPS), also known as axial offset anomaly (AOA), at PWRs and resulted in demonstrable improvements in radiological performance at both PWRs and BWRs. HE-UFC™ has also been credited with arresting persistent debris-induced fuel failures at several units through the removal of debris from fuel bundle bottom nozzles (thereby preventing debris transport into the fuel bundles during subsequent operation). The HE-UFC™ cleaning process takes approximately 3 minutes per fuel bundle and de-channeling is not required for BWR fuel.

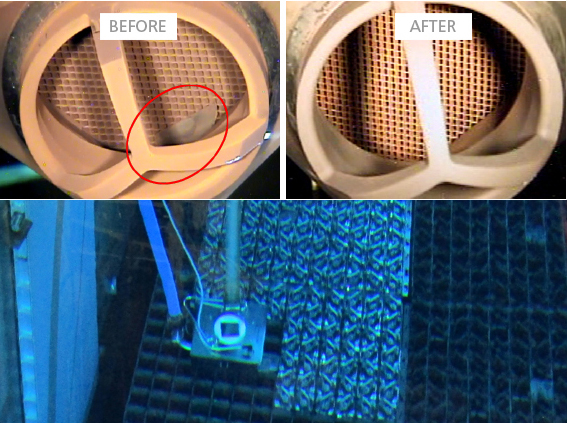

Bottom Nozzle Debris Elimination (BNDE™)

Similar to HE-UFC™, BNDE™ uses a combination of ultrasonic energy and reverse flow to effectively clean fuel bundles. However, ultrasonic energy is applied only to the fuel bundle bottom nozzle to remove debris and foreign material in order to prevent and/or mitigate debris-related fuel failures. BNDE™ does not remove activated corrosion products from the fuel rods and therefore does not provide the radiological benefits of HE-UFC™. BNDE™ and HE-UFC™ require similar time and resources during refueling outages. Both HE-UFC™ and BNDE™ are considered industry best practices for maintaining fuel performance and reliability, and both technologies have been applied in order to address INPO IER-L2-19-6 (Preventing Debris-Induced Fuel Failures).

Other Ultrasonic Decontamination Solutions

In addition to ultrasonic cleaning of nuclear fuel, Dominion Engineering, Inc. also offers a number of other Ultrasonic Cleaning & Decontamination solutions for piping, tanks, vessels, radwaste processing and solidification systems, BWR jet pumps, steam generators, and similar components. These ultrasonic cleaning products have been deployed successfully to reduce dose rates and restore performance in a wide range of component geometries and applications. Dominion Engineering, Inc. novel AMFM™ filter technology also uses a patented ultrasonic cleaning process to regenerate the capacity of these filters as needed. In addition to the products above, Dominion Engineering, Inc. regularly customizes ultrasonic cleaning and filtration solutions for customer-specific applications. Our unique combination of innovative equipment design and engineering analysis capabilities ensures safe and effective cleaning of nuclear components.