Smart-Sip™ is a significant advancement in fuel leak detection and characterization technology. Dominion Engineering, Inc. also offers a suite of other fuel inspection and diagnostic tools, including full length and bottom nozzle visual inspection systems, as well as a fuel crud sampling system that can be used in lieu of crud scraping for fuel crud and chemistry diagnostics.

Smart-Sip™ High Definition Vacuum Canister Fuel Sipping

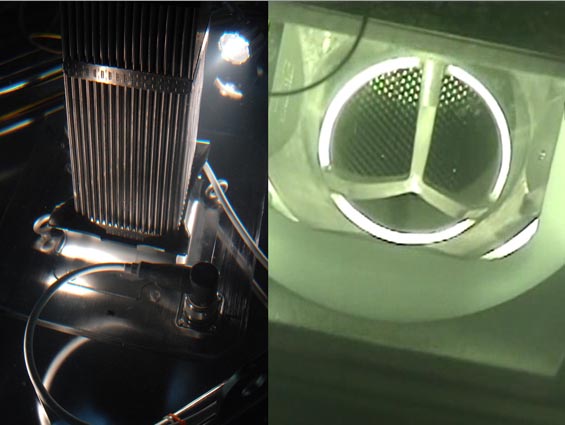

Vacuum canister sipping is a sensitive fuel leak detection method and the preferred technique for verifying fuel cladding integrity prior to dry cask storage and for identifying leaking fuel bundles during refueling outages. Nevertheless, traditional vacuum canister sipping sometimes fails to identify tight leaks fuel bundles and is not adequate for sizing cladding breaches. Smart-Sip™ incorporates a patented inline fission gas removal system that facilitates much higher fidelity fuel leak detection and characterization capabilities than can be achieved with traditional vacuum canister sipping equipment. Using the Smart-Sip™ system, hairline cracks and pinholes may be identified and dispositioned, allowing for better differentiation between fuel bundles that are damaged and those that are acceptable for return to service or dry cask storage.

Fuel Inspection Systems

Dominion Engineering, Inc. also offers a number high resolution visual inspection systems that can be integrated with its other fuel cleaning and fuel services products for a more comprehensive characterization of the condition of the fuel. This includes a 4-face visual inspection system that can be integrated with Dominion Engineering, Inc. HE-UFC™ equipment to generate before and after images of all four faces of the fuel bundle in parallel with HE-UFC™ cleaning (no added time for visual inspection). Dominion Engineering, Inc. also offers an analogous bottom nozzle visual inspection system, which can be used during HE-UFC™ or BNDE™ to monitor the removal of foreign material and debris from the bottom nozzle of the fuel bundles.

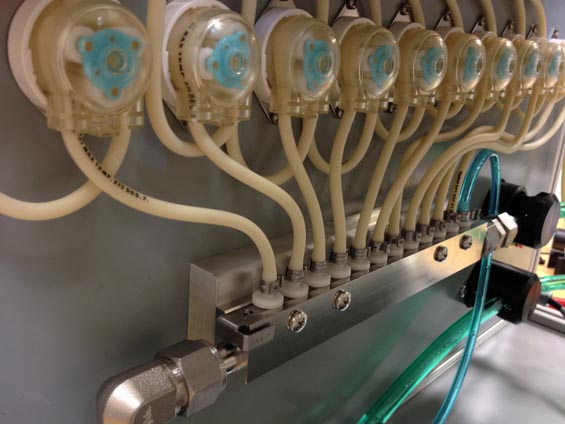

Fuel Crud Sampling System

Dominion Engineering, Inc. fuel crud sampling system facilitates controlled crud collection during fuel cleaning activities for subsequent chemistry and radiological diagnostics, such as analysis for the presence of zinc, noble metals or other chemical additives or impurities in the fuel crud. The crud sampling system integrates with Dominion Engineering, Inc. HE-UFC™ equipment and control software to allow collection of crud samples from specific fuel bundles and even specific spans along a fuel bundle. It is cost-effective to collect fuel crud concurrently with HE-UFC™ operations, rather than as a separate activity, and the crud sampling system has been successfully used in lieu of crud scrapes to characterize fuel crud composition. It has also been used as a secondary measurement for crud mass removal during HE-UFC™.