In addition to specialized equipment for ultrasonic cleaning of irradiated nuclear fuel, such as HE-UFC™ and BNDE™, Dominion Engineering, Inc. offers a wide range of products and technology for ultrasonic cleaning of other nuclear systems and components including: piping, tanks, vessels, filtration and demineralization systems, radwaste processing and solidification systems, BWR jet pumps, steam generators and similar components. In addition to the products above, Dominion Engineering, Inc. regularly customizes ultrasonic cleaning and filtration solutions for customer-specific applications. Our unique combination of innovative equipment design and engineering analysis capabilities ensures safe and effective cleaning of nuclear components.

Non-Intrusive Ultrasonic Decontamination (NU-DEC™)

NU-DEC™ systems can be installed on the exterior of piping, tanks and vessels and effectively clean the interior of these components without the need to open or enter the components or connected systems. NU-DEC™ systems are easy to install and cost-effective compared to equipment repair/replacement or chemical decontamination, particularly when contamination is localized or recurrent. NU-DEC™ systems have been successfully used in a wide range of applications at nuclear facilities, including decontamination of piping to reduce radiation exposure at operating nuclear plants and prior to decommissioning / dismantling of nuclear facilities and systems. For each application, Dominion Engineering, Inc. provides supporting engineering analysis to optimize cleaning parameters for safe and effective cleaning.

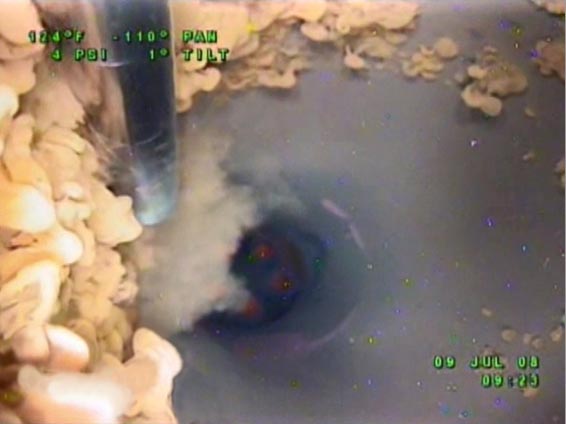

BWR Jet Pump Cleaning

BWR jet pumps, which circulate coolant inside BWR reactors, are susceptible to fouling at the nozzle inlet and throat which can lead to accelerated wear and performance degradation. Accelerated wear of Stellite™ surfaces also increases the rate of ingress of cobalt to BWR reactor systems, and thus increases plant dose rates. Dominion Engineering, Inc. offers a patented system and process for safe and effective ultrasonic cleaning of the interior of BWR jet pumps. The process involves insertion of a combined ultrasonic cleaning and vacuuming head inside the jet pumps to remove deposits from the interior of the jet pump. This process can extend the life and increase the performance of the jet pumps and is cost-effective relative to jet pump repairs.

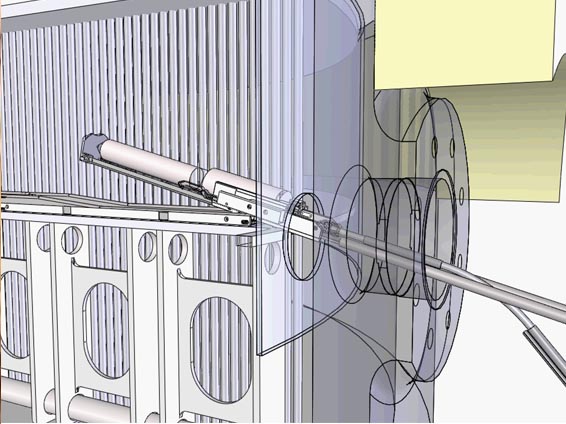

Steam Generator Ultrasonic Energy Cleaning (UEC)

Tenacious deposits form in difficult-to-access crevices on the secondary side of PWR and CANDU steam generators (SGs), such as on the tubesheet and in tube support plates. These deposits can cause tube denting and degradation, and disrupt normal thermal hydraulic performance in the SGs. Dominion Engineering, Inc. UEC process effectively disrupts and removes deposits from tubesheet crevices and other difficult-to-access locations in steam generators and other heat exchangers. To facilitate the UEC process, custom ultrasonic transducers and deployment tooling are typically installed through access ports near the SG tubesheet. Ultrasonic energy is then applied in water or a cleaning solution such as ASCATM to disrupt and remove the deposits. UEC deployment tooling is available for most PWR and CANDU SG designs.